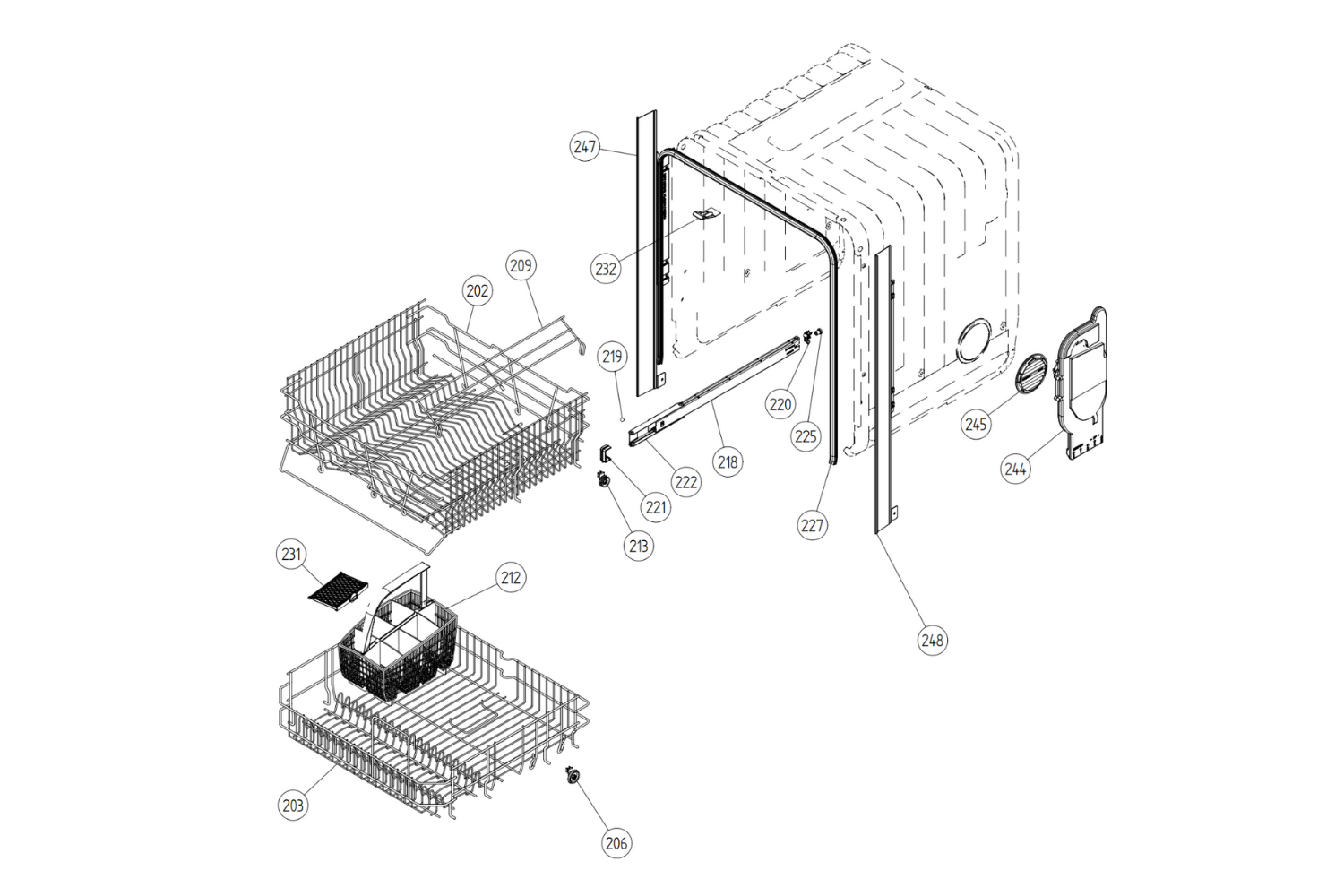

Cutting corners on Asko dishwasher parts can quietly turn a small repair into an expensive problem. Owning an Asko machine means you value Scandinavian design, sturdy steel construction, and a dishwasher that should run smoothly for many years. Even with that “more steel, less plastic” build, every appliance eventually needs a new seal, pump, or heating element.

When that time comes, it is tempting to reach for cheap, “universal” parts that claim to fit all Asko appliances and seem like a quick fix. Those non-genuine parts often do not match Asko’s tight engineering standards, which can lead to weaker cleaning, noisy cycles, leaks, and even safety risks.

Homeowners in Southern California and Las Vegas often discover this after a repeat breakdown and then book a follow-up visit with a specialist, such as Wilshire Refrigeration, to undo earlier shortcuts. Starting with factory-certified components helps reduce repeat failures, limit hidden water damage risk, and keep repair costs more predictable over time.

Engineering Precision Behind the Brand

Engineering precision is the main reason Asko appliances react badly to generic replacement parts. Asko dishwashers are built with tighter tolerances than many mainstream models, so part fit and material quality matter more than most owners expect. To understand why many “universal” Asko parts fail, it helps to look at the stainless steel, electronics, and water controls that make this brand different.

Superior Stainless Steel Construction Standards

Superior stainless steel construction is a core feature of an Asko dishwasher, and it shapes how every internal part must perform. Many models rely heavily on stainless steel for durability and reduced flex, which means replacement parts need compatible tolerances and materials to avoid premature wear at connection points. When low-cost replacement parts use softer metals or plastic instead of matching Asko’s standards, stress builds at connection points, and those parts wear out much faster than the originals.

Complex Integration of Sensitive Electronic Sensors

Sensitive electronic sensors are another reason generic components struggle in Asko dishwasher repair. These machines use multiple sensors to track water temperature, water level, spray pressure, and even how dirty the water is, so the control board can adjust each cycle in real time. A “universal” sensor or heating element may send signals that are slightly off, which can confuse the control board and trigger error codes or half-finished cycles. Over time, inconsistent readings can trigger error codes, interrupt cycles, or contribute to extra wear on components that rely on stable temperature and fill control.

Specific Calibration for Water Efficiency

Asko dishwashers are also calibrated for very precise water use, which is especially important in dry regions like Southern California and Las Vegas. The nozzles, pumps, and valves are sized to deliver exact water pressure and volume, so each load gets full coverage without wasting water.

If you install generic Asko parts that are not designed for these settings, the spray pattern and pressure can change just enough to leave dishes dirty or put extra strain on the pump. Even a small change in flow or spray pattern can increase strain on the pump or leave residue behind, which may reduce reliability over time.

Critical Dangers Posed by Non-Genuine Components

Non-genuine Asko dishwasher parts can create serious risks that go far beyond a simple inconvenience. What looks like a minor mismatch in shape or material can lead to leaks, electrical issues, and complete system failure over time. These dangers often show up slowly, which makes them easy to miss until costly damage has already been done.

- Incompatible material hardness: Some generic gears, couplings, and brackets use softer plastics or lower-grade alloys. Under load, those parts can round off, crack, or shed debris that interferes with nearby moving components.

- High-risk water leaks: Poorly formed seals and gaskets are a common weak point with off-brand Asko parts. If a seal does not sit flush, slow seepage can reach surrounding cabinets or flooring. Over time, trapped moisture can warp wood and increase mold risk, especially when leaks stay hidden.

- Electrical safety hazards: Generic heating elements, sensors, or connectors may not match the correct wattage range, connector fit, or thermal protection requirements for a specific Asko model. Overheating or loose connections can damage wiring, trip breakers, or knock the unit offline.

- Reduced warranty support: Non-certified parts can complicate warranty eligibility. If a failure is linked to a non-approved component, coverage for that repair may be denied, leaving parts, labor, and related damage as out-of-pocket costs.

Long-Term Benefits of Factory-Certified Replacements

Factory-certified Asko dishwasher parts help your appliance work the way the original engineers intended. These components are built to match the exact materials, sensors, and water patterns inside each model, which protects both performance and safety. Choosing genuine parts and working with qualified Asko service providers sets your dishwasher up for many more years of reliable use.

Preservation of Original Manufacturer Warranty Coverage

Using factory-certified parts is one of the simplest ways to keep your Asko warranty intact. When repairs follow the brand’s guidelines and use approved components, the manufacturer is more likely to stand behind the appliance if another issue appears later. That protection can help reduce unexpected out-of-pocket costs if another covered issue appears later.

Assurance of Exact Fit for Leak-Proof Operation

Factory-certified parts are designed for an exact fit inside Asko appliances, which helps prevent leaks and vibration. Correctly sized gaskets, valves, and pumps sit securely against the stainless steel tub and plumbing lines, helping support leak-resistant operation. That precise fit is especially important for built-in dishwashers in custom kitchens, where even a small leak can damage high-end cabinets and flooring.

Restoration of Whisper-Quiet Cleaning Performance

Genuine Asko parts also restore the quiet, smooth operation that many owners love about these dishwashers. Correct motors, pumps, and spray arms move with less strain, so cycles sound more like a low hum than a loud roar. Replacing worn components with factory-certified parts often restores the low-noise operation and steady cleaning performance expected from the brand.

Frequently Asked Questions

Why are genuine Asko dishwasher parts more expensive than generic ones?

Genuine Asko dishwasher parts cost more because model-specific fit and tolerances tend to be more consistent, and materials are selected to match how the dishwasher is engineered to run.

Can I use universal parts for my Asko dishwasher repair?

Using universal parts for Asko dishwasher repair is not recommended because they are not calibrated for Asko’s sensors, water pressure, and heating system, which can lead to more damage and repeat service calls.

How can I tell if a part is a genuine Asko component?

You can usually confirm a genuine Asko part by looking for branded packaging, a verifiable serial number, and purchasing only through authorized Asko service providers or certified distributors.

Does using non-original equipment manufacturer (OEM) parts void my Asko warranty?

Using non-OEM parts can affect warranty coverage, especially if a later failure is linked to a non-approved component. Warranty terms vary by model and purchase date, so checking the written warranty language matters.

Where can I find a technician who uses factory-certified Asko parts?

In Southern California and Las Vegas, look for an appliance repair provider that documents part numbers used, confirms factory-certified sourcing, and has experience with Asko service. Wilshire Refrigeration is one option to consider, and the key is verifying that certified parts are used before work begins.

Protecting Your Asko Dishwasher With Genuine Parts

An Asko dishwasher is a long-term investment in your kitchen, so it makes sense to protect it with genuine parts and skilled service rather than take chances on generic substitutes. Factory-certified Asko dishwasher parts are built to match the brand’s stainless steel design, sensitive electronics, and water-efficient cycles, which help prevent leaks, electrical problems, and early failures. Choosing authentic components also supports warranty coverage and maintains strong cleaning performance, so dishes come out clear and spotless after every cycle.

For households in Southern California and Las Vegas, working with a specialist like Wilshire Refrigeration adds another layer of protection, because repairs are handled by technicians who understand the brand’s exact standards. Choosing certified parts and qualified Asko service helps protect the kitchen, the appliance, and long-term performance.