Neglecting refrigerator maintenance often leads to higher costs down the line than the service itself. When a fridge runs day and night without routine care, parts wear out faster, energy use climbs, and surprise breakdowns can lead to spoiled food and emergency repairs.

In busy homes across Southern California and Las Vegas, Wilshire Refrigeration & Appliance Inc. sees how neglected coils, loose door seals, and minor issues turn into major problems that could have been prevented with a simple yearly visit. A small investment in professional service helps a refrigerator stay colder, run smoother, and last longer, making proactive care one of the smartest financial decisions a homeowner can make for the kitchen.

How Does Routine Care Extend Fridge Life?

Routine care extends the lifespan of a refrigerator by reducing strain on key parts and catching small issues before they turn into failures. Regular refrigerator maintenance also helps the unit run closer to how it performed when it was new, which means fewer surprises and better food safety. Simple fridge maintenance, backed up with professional service, can keep a hard-working appliance going strong for many years.

Prevention of Compressor Burnout Due to Dirty Coils

Preventing compressor burnout starts with keeping the condenser coils clean. When coils are covered in dust or pet hair, the refrigerator has to work harder to release heat, which pushes the compressor to run longer and hotter. Over time, that extra strain can shorten compressor life and lead to one of the most expensive types of repairs. Routine refrigerator maintenance that includes coil cleaning helps protect this critical part and supports a longer overall lifespan.

Early Detection of Worn Door Gaskets and Seals

Early detection of worn door gaskets and seals keeps cold air in and warm air out. When gaskets crack, flatten, or pull away from the frame, the fridge and freezer lose cool air, and the system has to run more often to stay at the right temperature. During a maintenance visit, a technician can spot weak or damaged seals, recommend replacement if needed, and keep the doors closing tightly so the appliance does not overwork.

Lubrication of Motor Bearings to Reduce Friction

Lubrication of motor bearings reduces friction and helps fans and moving parts turn smoothly. Dry or worn bearings can create noise, heat, and extra drag, which puts stress on motors and can lead to early failure. As part of professional fridge maintenance, a technician may inspect and lubricate specific moving parts so they run easily, helping the entire system last longer and stay quieter.

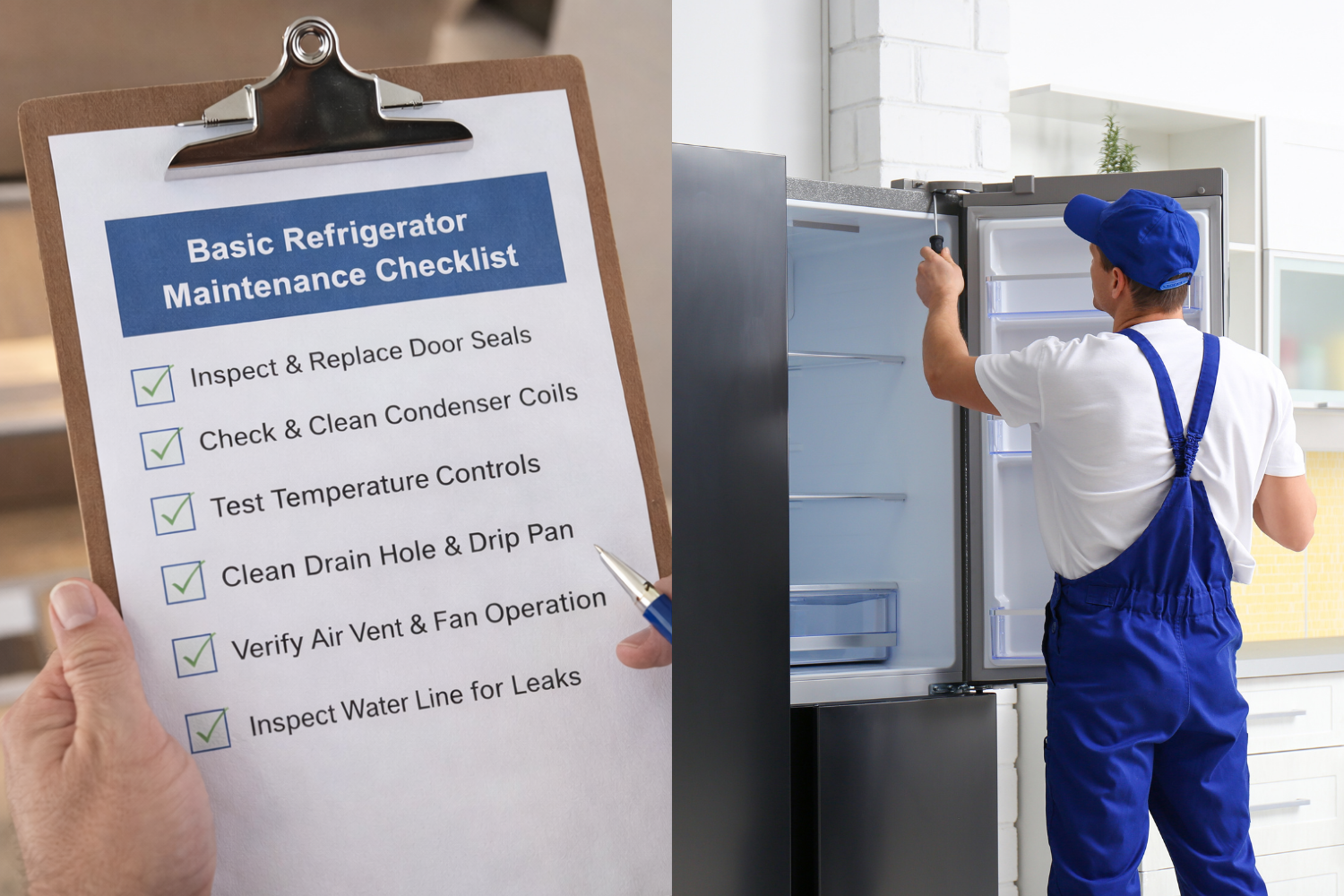

Difference Between DIY Cleaning and Professional Service

The main difference between do-it-yourself cleaning and professional service is the depth of inspection and testing. A homeowner can follow a basic refrigerator maintenance checklist for tasks like wiping shelves, cleaning gaskets, and vacuuming easy-to-reach coils. A factory-certified technician goes much further, checking internal parts and making precise adjustments that are not easy or safe for most homeowners to perform alone.

Calibration of Internal Thermostats and Sensors

Calibration of internal thermostats and sensors makes sure the refrigerator and freezer hold accurate temperatures. When these controls drift even a few degrees, food can spoil faster or freeze when it should not. During professional refrigerator maintenance, a technician can compare real temperatures to the control settings and make corrections so the system cools as designed and does not run longer than needed.

Clearing of Hidden Drain Lines to Prevent Leaks

Clearing hidden drain lines helps prevent leaks, ice buildup, and musty odors. Drain tubes that carry water away during defrost cycles can slowly clog with debris or ice, sending water into the bottom of the fridge or onto the floor. A trained technician knows where these lines run inside different models and can clear blockages safely, which is not always easy to do without taking panels apart.

Verification of Refrigerant Levels and Pressures

Verification of refrigerant levels and pressures is a critical step that requires specialized gauges and training. Low or incorrect refrigerant levels can cause poor cooling, short cycling, or even compressor damage. Professional service includes checking these pressures against the manufacturer’s specifications and looking for signs of leaks, something that is not part of typical DIY fridge maintenance.

Do Different Fridge Brands Need Different Care?

Luxury and standard brands do require different maintenance protocols because the internal designs are not the same. A built-in luxury unit often uses advanced features and more complex systems than a standard freestanding refrigerator. Proper maintenance takes the brand’s design and engineering into account to ensure every unit receives the care it needs.

Dual Compressor Testing for Luxury Refrigerator Maintenance

Dual-compressor testing is a key part of Sub-Zero refrigerator maintenance and of service for many other luxury built-in brands that use separate cooling systems for the refrigerator and freezer. These advanced designs give better temperature control and food preservation, but also include more components that need careful testing. A factory-certified technician can test both compressors, check the start components, and confirm that each system holds proper pressures, which helps protect a high-end appliance from early failure and performance issues.

Standard Component Checks for Freestanding Refrigerator Maintenance

Standard component checks are central to freestanding refrigerator maintenance and help keep everyday kitchen models running reliably. A technician will usually inspect the condenser fan, evaporator fan, temperature controls, defrost system, and door gaskets in a careful sequence, confirming that each part is working correctly and not putting extra strain on the compressor. This kind of structured refrigerator maintenance checklist helps catch small issues early and supports a longer, more efficient life for the appliance.

Software Updates for Smart and Integrated Appliances

Software updates for smart and integrated appliances are becoming a more common part of refrigerator maintenance. Some modern luxury and mid-range models connect to a home network or use internal control boards that can receive firmware updates. A technician may update software, reset error codes, and confirm that sensors and features are communicating correctly, which supports both performance and long-term reliability.

Why Does Freezer Maintenance Matter?

Freezer maintenance is just as critical as fridge care because both sections often share the same cooling system. Problems that start in the freezer can make the entire refrigerator work harder, which shortens its life and raises energy use. Regular attention to the freezer side keeps the whole appliance in balance.

Removal of Ice Buildup on Evaporator Fans

Removal of ice buildup on evaporator fans keeps air moving evenly through the freezer and into the refrigerator section. If ice blocks the fan blades or shrouds, air cannot circulate, which can create warm spots and overworked components. During freezer maintenance, a technician checks for frost around the fan area and addresses the cause, such as a defrost problem or door seal issue.

Inspection of Defrost Heaters and Timers

Inspection of defrost heaters and timers helps prevent heavy frost from forming on the evaporator coils. When the defrost system fails, ice builds up, blocks airflow, and makes the compressor run longer to keep temperatures low. Regular service includes testing these parts to confirm that defrost cycles are happening as intended so the freezer can stay frost-controlled without wasting energy.

Testing of Ice Maker Solenoids and Fill Tubes

Testing of ice maker solenoids and fill tubes helps avoid leaks, clogs, and ice production issues. A sticking water valve, kinked tube, or slow fill can cause small floods inside the freezer or poor ice quality. During fridge and freezer maintenance, a technician can activate the ice maker, check water flow, and look for signs of mineral buildup or damage in these small but important parts.

How Does Maintenance Cut Energy Costs?

Maintenance impacts energy efficiency and utility bills by helping the refrigerator remove heat more easily and run for shorter cycles. A clean, well-sealed appliance does not need to work as hard to stay cold, which lowers electricity use over time. In high-use kitchens across Southern California and Las Vegas, this difference can show up clearly on monthly bills.

Improved Heat Exchange Through Clean Condenser Coils

Improved heat exchange through clean condenser coils lets the refrigerator release heat quickly and with less effort. When dust and debris coat the coils, the unit has to run longer to reach the same temperature, which drives up energy use. Regular refrigerator maintenance that includes coil cleaning keeps this surface clear so the system stays efficient.

Proper Airflow Circulation Throughout the Cabinets

Proper airflow circulation throughout the cabinets keeps temperatures even from top to bottom. Blocked vents, overloaded shelves, or frozen passages can force the fridge to run longer and cause hot and cold spots that spoil food. During professional service, a technician can check airflow paths, fan operation, and common problem areas, then suggest simple layout or loading changes that support better performance.

Reduction in Costly Energy Spikes and Waste

Reduction in costly energy spikes and waste is a major benefit of planned maintenance. A refrigerator that struggles with dirty coils, bad seals, or failing parts often shows short, frequent run cycles that drive up power use. Keeping up with a refrigerator maintenance checklist and scheduling yearly visits helps the appliance run in a steady, efficient pattern, which can lower total energy costs over its lifetime.

Frequently Asked Questions

How often should refrigerator maintenance be done?

Refrigerator maintenance is usually recommended once a year, especially for busy homes or luxury units in warm areas like Southern California and Las Vegas.

What is included in professional refrigerator maintenance?

Professional refrigerator maintenance typically includes coil cleaning, gasket checks, temperature calibration, drain line clearing, electrical and mechanical inspections, and tests specific to the brand.

Can I vacuum refrigerator coils myself?

Yes, many homeowners can vacuum exposed refrigerator coils as part of basic fridge maintenance, but deep cleaning and internal checks are best handled by a factory-certified technician.

How long should a refrigerator last with proper maintenance?

With regular refrigerator maintenance and freezer maintenance, many modern units can often run well for 10 to 15 years or more, depending on brand and usage.

Do I really need to service my Sub-Zero refrigerator annually?

Annual Sub-Zero refrigerator maintenance is strongly recommended to protect dual compressor systems, advanced controls, and the overall performance of a high-end built-in appliance.

Schedule Your Factory Certified Service Now

Annual refrigerator maintenance costs far less than a major repair or the early replacement of a luxury unit. A factory-certified visit does more than clean parts. It ensures your kitchen’s most important appliance stays dependable, efficient, and long-lasting.

Wilshire Refrigeration provides this level of expert care for Sub-Zero, Wolf, Cove, and many other premium brands throughout Southern California and Las Vegas. Scheduling service with a certified technician is one of the most effective ways to safeguard appliance performance, control energy use, and protect the investment made in a high-quality kitchen.